The created PCBs undergo electrical tests to make certain all circuits are linked properly and fulfill design specifications.

Components with cold solder joints may well fail to establish electrical connections, causing functional failure.

A printed circuit board (PCB) is a unadorned board with conductive routes that act as The premise for electronic circuits, while a printed circuit assembly (PCBA) is a totally mounted board that adds electronic components. PCBs are non-functional in themselves, though PCBA is ready to be used in electronic units. The table below reveals the significant difference between PCB and PCBA: Facet PCB (Printed Circuit Board) PCBA (Printed Circuit Board Assembly) Definition A bare board with copper traces but no electronic components. A fully assembled board with all vital electronic components soldered.

modifications for the substrate, ordinarily to create "versatile transistors" for a versatile display or other adaptable electronics, quite possibly resulting in a roll-absent Laptop.

When utilizing the --prefix solution works, It's important to explicitly utilize it every time you produce an ecosystem. If you just want your environments stored somewhere else by default, you may configure it with your .condarc file.

Increased Insulation: As PCBs turn out to be thinner and trace widths lessen, insulation problems in between conductors become far more pronounced. The insulation properties of the solder mask are very important in stopping small circuits.

The Motorola 6800 number of Computer system-linked chips, leading to the 68000 and 88000 collection (the 68000 sequence was really productive keyboard Solution and was Employed in the Apple Lisa and pre-PowerPC-based mostly Macintosh, Commodore Amiga, Atari ST/TT/Falcon030, and Subsequent family members of personal computers, along with a lot of types of workstations and servers from a lot of manufacturers in the 80s, in conjunction with all kinds of other techniques and products)

The PCBA Factory temperature profile is crucial throughout the reflow soldering course of action. It is often divided into four zones: the preheat zone, thermal soak zone, reflow zone, and cooling zone.

Utilized in healthcare models wherever There exists a better require for precision and compliances to clinical units. three. Military PCBA

Now you ought to have a further knowledge of PCBA. It is The idea of electronic devices and varieties a complete circuit by assembling the demanded components with a circuit board. The emergence of PCBA has simplified the PCBA Factory connection way of electronic components and furnished a far better order for The interior connections of electronic equipment.

I thought that was rather wild. The reality that something related is happening for fifty a long time is really amazing."

Soon after soldering, the PCBs need to be cleaned making use of acceptable ways to clear away flux residues as well as other contaminants, avoiding corrosion.

Just about every move, from initial inspections to last assembly, is designed to be sure trustworthiness and overall performance. By understanding these distinctions as well as intricacies of production workflows, clients can obtain Perception into makers' procedures and expert services, fostering mutual belief, developing collaboration intentions, and boosting conversation effectiveness. By comprehending these distinctions as well as the intricacies of manufacturing workflows, shoppers can acquire insight into brands' processes and providers, fostering mutual have confidence in, setting up collaboration intentions, and boosting conversation efficiency.

After you’re trying to find a PCB Assembly Company, choose one whose Key enterprise is producing PCBA, not brokering or maybe giving providers.

Danny Pintauro Then & Now!

Danny Pintauro Then & Now! Nancy McKeon Then & Now!

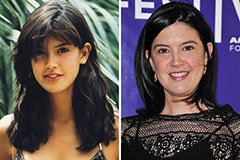

Nancy McKeon Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now! Traci Lords Then & Now!

Traci Lords Then & Now! Heather Locklear Then & Now!

Heather Locklear Then & Now!